- By: admin

- Category: Commercial Floor Cleaning Machines

- 0 comment

In the world of commercial and industrial cleaning, maintaining equipment is paramount to ensuring efficiency and effectiveness. As contract cleaners, building managers, and facility managers navigate the complexities of their roles, understanding when to replace or repair cleaning equipment becomes a critical aspect of their responsibilities. This article delves into the various factors that influence the lifespan of cleaning equipment, providing insights that can help professionals make informed decisions.

From recognising signs of wear and tear to considering environmental impacts, we will explore the essential elements that contribute to the longevity and performance of cleaning tools. Please feel free to get in touch with us through our Contact Us page for any inquiries or assistance.

Summary

- Signs of Wear and Tear: Look out for fraying bristles, cracks in the handle, or any other visible damage to the cleaning tool.

- Frequency of Use: Consider how often the tool is being used and whether it is being used for heavy-duty or light cleaning tasks.

- Type of Surface Being Cleaned: Different surfaces may require different types of cleaning tools, so consider the specific needs of the surfaces in your home.

- Performance Decline: If you notice a decline in the tool’s effectiveness, it may be time to replace it.

- Visual Inspection: Regularly inspect the cleaning tool for any signs of damage or wear and tear.

- Manufacturer’s Recommendations: Follow the manufacturer’s guidelines for maintenance and replacement of the cleaning tool.

- Budget Considerations: Balance the cost of replacing the tool with the potential savings from improved cleaning efficiency.

- Environmental Impact: Consider the environmental impact of disposing of the old tool and purchasing a new one, and look for eco-friendly options if possible.

One of the most apparent indicators that cleaning equipment may need attention is visible wear and tear. This can manifest in various forms, such as frayed cords, cracked handles, or worn-out brushes. For instance, a commercial vacuum cleaner that has been in service for several years may show signs of fatigue, such as reduced suction power or a rattling sound during operation.

These signs not only affect the performance of the equipment but can also lead to safety hazards if left unaddressed. Moreover, wear and tear can also be less visible but equally detrimental. For example, the internal components of a floor scrubber may degrade over time, leading to inefficient cleaning cycles.

Regularly inspecting equipment for both obvious and subtle signs of deterioration is crucial. By doing so, facility managers can proactively address issues before they escalate into costly repairs or replacements, ensuring that cleaning operations remain smooth and effective.

Frequency of Use

The frequency with which cleaning equipment is used plays a significant role in determining its lifespan. Equipment that is used daily in high-traffic environments, such as shopping centres or hospitals, will naturally experience more wear than those used sporadically in less demanding settings. For instance, a carpet extractor employed in a busy hotel lobby will likely require more frequent maintenance than one used in an office environment where carpets are cleaned only once a month.

Understanding the usage patterns of your cleaning equipment can help in planning maintenance schedules effectively. For example, if a particular piece of equipment is used extensively, it may be wise to invest in higher-quality models designed for heavy-duty use. Conversely, lighter-duty equipment may suffice for less frequently used areas.

By aligning equipment choice with usage frequency, facility managers can optimise their cleaning operations while extending the life of their tools.

Type of Surface Being Cleaned

The type of surface being cleaned is another critical factor influencing the wear and tear on cleaning equipment. Different surfaces require different cleaning methods and tools; for instance, a hard floor surface like tile or concrete may necessitate a robust scrubber, while delicate surfaces like polished wood demand gentler treatment. Using inappropriate equipment for specific surfaces can lead to accelerated wear and potential damage.

Consider a scenario where a heavy-duty floor scrubber is used on a sensitive vinyl floor. The aggressive scrubbing action may not only wear down the scrubber’s brushes more quickly but could also damage the flooring itself, leading to costly repairs. Therefore, it is essential for facility managers to assess the surfaces within their premises and select appropriate cleaning equipment accordingly.

This not only preserves the integrity of both the equipment and the surfaces but also enhances overall cleaning effectiveness.

Performance Decline

As cleaning equipment ages or endures heavy use, its performance may begin to decline. This decline can manifest in various ways, such as reduced suction power in vacuums or ineffective chemical dispersion in pressure washers. For instance, a floor buffer that once left surfaces gleaming may start to leave streaks or fail to achieve the desired shine over time.

Such performance issues can significantly impact cleanliness standards in commercial environments. Monitoring performance metrics is vital for identifying when equipment is no longer meeting operational standards. Regular assessments can help determine whether a piece of equipment is still fit for purpose or if it’s time to consider repairs or replacements.

For example, if a carpet cleaner consistently fails to extract dirt effectively despite regular maintenance, it may be more cost-effective in the long run to invest in a new model rather than continuing to pour resources into an underperforming machine.

Visual Inspection

Conducting regular visual inspections of cleaning equipment is an essential practice for maintaining operational efficiency. A thorough inspection can reveal not only obvious signs of damage but also potential issues that could lead to more significant problems down the line. For instance, checking hoses for cracks or leaks can prevent water damage in sensitive areas and ensure that machines operate at peak efficiency.

During these inspections, it’s also important to assess the condition of consumables such as filters and pads. A clogged filter in a vacuum cleaner can drastically reduce its suction power, while worn pads on a floor scrubber can lead to subpar cleaning results. By incorporating visual inspections into routine maintenance schedules, facility managers can catch issues early and ensure that their cleaning equipment remains reliable and effective.

Manufacturer’s Recommendations

Manufacturers often provide guidelines regarding the maintenance and replacement schedules for their equipment. These recommendations are based on extensive testing and industry standards and should be taken seriously by facility managers and contract cleaners alike. Adhering to these guidelines can help extend the life of cleaning equipment and ensure optimal performance.

For example, if a manufacturer suggests replacing certain components after a specific number of hours of use or after a set period, it’s wise to follow these recommendations closely. Ignoring them could lead to unexpected breakdowns or diminished cleaning capabilities. Additionally, manufacturers may offer insights into best practices for using their equipment effectively, which can further enhance operational efficiency.

Budget Considerations

Budget constraints are an ever-present reality for many organisations involved in commercial and industrial cleaning. While it may be tempting to delay repairs or replacements to save costs in the short term, this approach can often lead to greater expenses down the line. Inefficient equipment can result in increased labour costs due to longer cleaning times or even damage to facilities that require costly repairs.

When evaluating budget considerations, it’s essential to weigh the costs of maintaining older equipment against the potential savings from investing in newer models. For instance, while purchasing a high-quality floor scrubber may require a larger upfront investment, its efficiency could lead to significant savings in labour costs and improved cleaning outcomes over time. By taking a long-term view on budgeting for cleaning equipment, facility managers can make more informed decisions that benefit both their operations and their bottom line.

Environmental Impact

In today’s environmentally conscious world, the impact of cleaning operations on the environment cannot be overlooked. The choice of cleaning equipment plays a significant role in determining this impact. For example, older machines may consume more energy or use harsher chemicals that are detrimental to both health and the environment.

Conversely, newer models often incorporate energy-efficient technologies and eco-friendly cleaning solutions. Facility managers should consider not only the operational efficiency of their cleaning equipment but also its environmental footprint. Investing in sustainable options not only aligns with corporate social responsibility goals but can also enhance an organisation’s reputation among clients and stakeholders.

For instance, using green-certified products and energy-efficient machines can significantly reduce an organisation’s overall environmental impact while maintaining high standards of cleanliness. In conclusion, understanding when to replace or repair cleaning equipment is crucial for contract cleaners, building managers, and facility managers alike. By recognising signs of wear and tear, considering usage frequency and surface types, monitoring performance decline, conducting visual inspections, adhering to manufacturer recommendations, evaluating budget considerations, and being mindful of environmental impacts, professionals can make informed decisions that enhance operational efficiency and sustainability.

**FAQs** 1. **How often should I inspect my cleaning equipment?**

Regular inspections should be conducted at least once a month or more frequently if the equipment is used heavily. 2.

**What are some common signs that my vacuum cleaner needs replacing?**

Look for reduced suction power, unusual noises during operation, or visible damage to hoses or filters. 3. **How do I determine if my floor scrubber is still effective?**

Monitor its performance; if it fails to clean effectively despite regular maintenance, it may be time for replacement.

4. **Are there specific guidelines for maintaining different types of cleaning equipment?**

Yes, manufacturers typically provide maintenance guidelines tailored to each type of equipment; always refer to these recommendations. 5.

**What are some eco-friendly options for commercial cleaning?**

Consider using energy-efficient machines and environmentally friendly cleaning products that are certified green or biodegradable.

FAQs

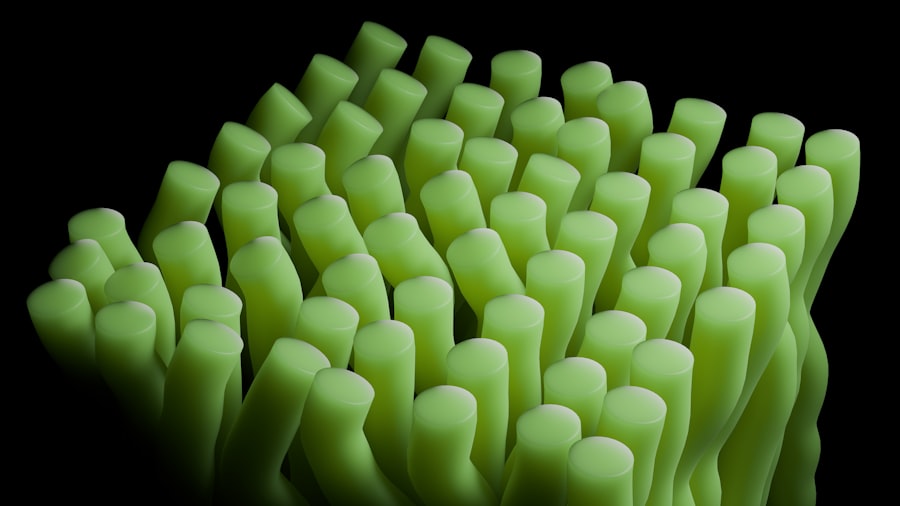

What are scrubber pads and brushes used for?

Scrubber pads and brushes are used in floor scrubbers to effectively clean and scrub various types of flooring surfaces, such as tile, concrete, and hardwood.

How often should scrubber pads and brushes be replaced?

The frequency of replacement for scrubber pads and brushes depends on the type of flooring being cleaned, the frequency of use, and the level of soiling. However, a general rule of thumb is to replace them when they show signs of wear and tear, such as fraying, flattening, or reduced cleaning effectiveness.

What are the signs that indicate scrubber pads and brushes need to be replaced?

Signs that indicate scrubber pads and brushes need to be replaced include fraying or splitting of the bristles, reduced cleaning effectiveness, visible wear and tear, and an inability to effectively remove dirt and grime from the floor surface.

Can using worn scrubber pads and brushes cause damage to the floor surface?

Yes, using worn scrubber pads and brushes can cause damage to the floor surface. Worn pads and brushes may not effectively remove dirt and grime, leading to the accumulation of debris that can scratch or damage the floor surface.

What are the benefits of replacing scrubber pads and brushes regularly?

Regular replacement of scrubber pads and brushes ensures optimal cleaning performance, extends the life of the floor scrubber machine, prevents damage to the floor surface, and maintains a hygienic and clean environment.