- By: admin

- Category: Commercial Floor Cleaning Machines

- 0 comment

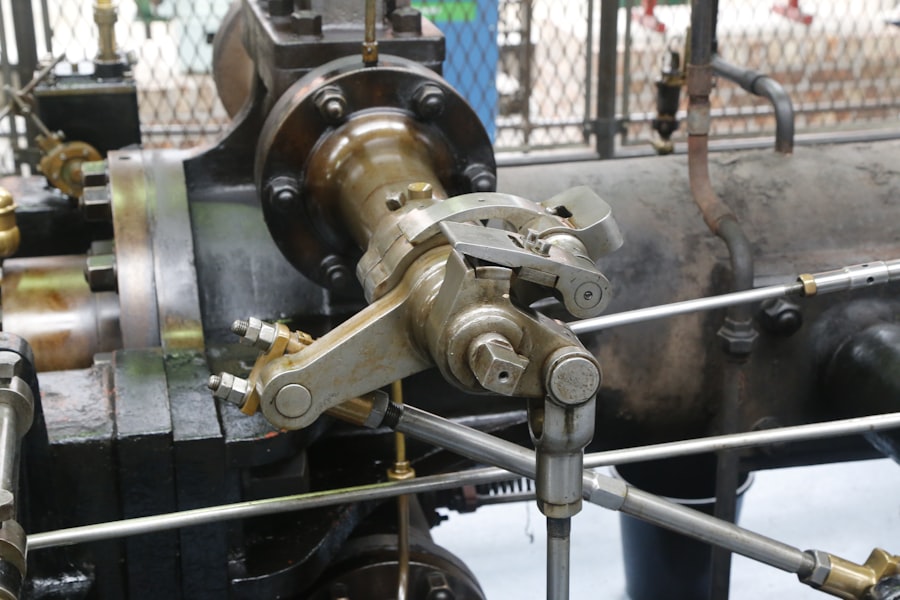

In the fast-paced world of commercial and industrial operations, the significance of cleanliness cannot be overstated. Tailored industrial cleaning equipment has emerged as a vital component in maintaining hygiene, safety, and efficiency across various sectors. Unlike generic cleaning tools, these specialised solutions are designed to meet the unique demands of specific industries, ensuring that every nook and cranny is addressed with precision.

As businesses strive to uphold their reputations and comply with stringent regulations, investing in tailored cleaning equipment becomes not just a choice but a necessity. The evolution of cleaning technology has paved the way for innovations that cater to the diverse needs of different industries. From high-pressure washers to advanced sanitisation systems, tailored cleaning equipment is engineered to tackle the unique challenges faced by sectors such as food and beverage, pharmaceuticals, and manufacturing.

This article delves into the importance of industry-specific cleaning solutions and explores how they enhance operational efficiency while ensuring compliance with health and safety standards.

Summary

- Tailored industrial cleaning equipment is designed to meet the specific needs of various industries, providing efficient and effective cleaning solutions.

- Industry-specific cleaning equipment is crucial for maintaining high standards of cleanliness and hygiene in different sectors, such as food and beverage, automotive, pharmaceutical, manufacturing, aerospace, oil and gas, healthcare, and electronics.

- The food and beverage industry requires tailored cleaning solutions to meet strict hygiene and safety regulations, including equipment designed for sanitizing production lines and processing equipment.

- The automotive industry benefits from customized cleaning equipment that can effectively remove grease, oil, and other contaminants from vehicle components and manufacturing facilities.

- The pharmaceutical industry relies on specialized cleaning solutions to ensure the cleanliness and sterility of production areas and equipment, helping to maintain product quality and safety.

Understanding the Importance of Industry-Specific Cleaning Equipment

The importance of industry-specific cleaning equipment cannot be overstated, particularly in environments where hygiene is paramount. Each industry has its own set of regulations and standards that dictate how cleanliness should be maintained. For instance, the food and beverage sector must adhere to strict health codes to prevent contamination, while the pharmaceutical industry requires sterile environments to ensure product integrity.

Generic cleaning tools simply cannot meet these rigorous demands; hence, tailored solutions are essential. Moreover, using equipment designed for specific applications can significantly enhance productivity. For example, in a manufacturing facility, using a high-efficiency particulate air (HEPA) vacuum can effectively remove fine dust particles that could compromise product quality.

Similarly, in the healthcare sector, specialised disinfecting equipment can ensure that surfaces are not only clean but also free from harmful pathogens. By investing in tailored cleaning solutions, businesses can streamline their operations, reduce downtime, and ultimately save costs associated with non-compliance or product recalls.

Tailored Cleaning Solutions for the Food and Beverage Industry

In the food and beverage industry, cleanliness is not just about aesthetics; it is a critical factor in ensuring consumer safety. Tailored cleaning solutions are designed to meet the stringent hygiene standards set by regulatory bodies. For instance, food processing plants require equipment that can withstand high temperatures and aggressive cleaning agents without compromising their integrity.

Customised pressure washers and sanitising systems are often employed to ensure that all surfaces are thoroughly cleaned and sanitised. Additionally, the layout of food production facilities often presents unique challenges. Equipment must be able to navigate tight spaces and reach high areas where contaminants may accumulate.

Tailored cleaning solutions such as compact scrubbers and extendable wands are designed specifically for these environments, allowing for efficient cleaning without disrupting production processes. By utilising industry-specific cleaning equipment, businesses can maintain high hygiene standards while minimising operational disruptions.

Customized Cleaning Equipment for the Automotive Industry

| Equipment Type | Features | Benefits |

|---|---|---|

| Parts Washer | High-pressure spray, heated cleaning solution | Efficient removal of grease and grime from automotive parts |

| Conveyor Belt Washer | Automated cleaning process, adjustable speed | Continuous cleaning of automotive components with minimal manual intervention |

| Ultrasonic Cleaner | Uses ultrasonic waves to clean intricate parts | Gentle yet effective cleaning of delicate automotive components |

The automotive industry is characterised by its complex manufacturing processes and stringent quality control measures. As such, customised cleaning equipment plays a crucial role in maintaining cleanliness throughout production lines. From assembly plants to paint shops, each area has its own unique cleaning requirements that generic tools simply cannot fulfil.

For example, specialised degreasers and solvent-based cleaners are essential for removing oil and grease from machinery without damaging sensitive components. Moreover, the automotive sector often deals with hazardous materials that require careful handling. Tailored cleaning solutions such as spill containment systems and industrial vacuums equipped with HEPA filters are vital for ensuring that any spills or debris are managed safely and effectively.

By investing in customised cleaning equipment, automotive manufacturers can not only enhance their operational efficiency but also ensure compliance with environmental regulations.

Specialized Cleaning Solutions for the Pharmaceutical Industry

In the pharmaceutical industry, maintaining a sterile environment is paramount to ensuring product safety and efficacy. Tailored cleaning solutions are specifically designed to meet the rigorous standards set by regulatory agencies such as the Therapeutic Goods Administration (TGA) in Australia. This includes using specialised disinfectants that are effective against a broad spectrum of pathogens while being safe for use in sensitive environments.

Furthermore, the design of pharmaceutical facilities often includes cleanrooms that require meticulous cleaning protocols. Customised cleaning equipment such as electrostatic sprayers and ultra-fine misting systems are employed to ensure that every surface is disinfected without introducing contaminants into the air. By utilising specialised cleaning solutions, pharmaceutical companies can uphold their commitment to quality while minimising the risk of contamination during production.

Tailored Industrial Cleaning Equipment for the Manufacturing Sector

The manufacturing sector encompasses a wide range of industries, each with its own unique cleaning challenges. Tailored industrial cleaning equipment is essential for maintaining operational efficiency and ensuring compliance with health and safety regulations. For instance, manufacturing facilities often deal with heavy machinery that generates significant amounts of dust and debris.

Customised industrial vacuums equipped with powerful suction capabilities are designed to handle these challenges effectively. Additionally, many manufacturing processes involve hazardous materials that require careful handling during cleanup. Tailored solutions such as chemical-resistant floor scrubbers and spill response kits are crucial for ensuring that any spills or leaks are managed safely and efficiently.

By investing in tailored industrial cleaning equipment, manufacturers can create a safer working environment while enhancing productivity and reducing downtime.

Custom Solutions for the Aerospace Industry

The aerospace industry operates under some of the most stringent cleanliness standards due to the critical nature of its products. Tailored cleaning solutions are essential for maintaining the integrity of aircraft components and ensuring safety during flight operations. For example, specialised ultrasonic cleaners are often used to remove contaminants from intricate parts without causing damage.

Moreover, aerospace facilities require cleaning equipment that can handle large-scale operations while adhering to strict environmental regulations. Customised pressure washers with eco-friendly detergents are designed to effectively clean aircraft exteriors while minimising environmental impact. By utilising tailored cleaning solutions, aerospace manufacturers can uphold their commitment to safety and quality while meeting regulatory requirements.

Industry-Specific Cleaning Equipment for the Oil and Gas Sector

The oil and gas sector presents unique challenges when it comes to cleanliness and safety. Tailored cleaning equipment is essential for managing spills, maintaining equipment integrity, and ensuring compliance with environmental regulations. For instance, specialised vacuum trucks equipped with advanced filtration systems are often employed to safely remove hazardous materials from drilling sites.

Additionally, the oil and gas industry frequently deals with corrosive substances that require careful handling during cleanup. Customised cleaning solutions such as chemical-resistant pressure washers and containment booms are vital for ensuring that spills are managed effectively without posing a risk to workers or the environment. By investing in industry-specific cleaning equipment, oil and gas companies can enhance safety while minimising their environmental footprint.

Tailored Cleaning Solutions for the Healthcare Industry

In the healthcare sector, cleanliness is critical for preventing infections and ensuring patient safety. Tailored cleaning solutions are designed to meet the unique demands of hospitals, clinics, and other healthcare facilities. For example, specialised disinfecting equipment such as foggers and electrostatic sprayers are employed to ensure that all surfaces are thoroughly sanitised without leaving any residue.

Moreover, healthcare facilities often have specific protocols for managing hazardous waste generated during medical procedures. Customised waste disposal systems are essential for ensuring that biohazardous materials are handled safely and in compliance with regulations. By utilising tailored cleaning solutions, healthcare providers can create a safe environment for patients while minimising the risk of healthcare-associated infections.

Customized Equipment for the Electronics and Semiconductor Industry

The electronics and semiconductor industry operates in an environment where even the smallest particle can compromise product quality. Tailored cleaning solutions are essential for maintaining cleanliness in cleanrooms where sensitive components are manufactured. For instance, specialised ionised air blowers are used to remove dust particles without generating static electricity that could damage electronic components.

Additionally, customised cleaning equipment such as ultra-pure water systems is crucial for ensuring that all surfaces are free from contaminants before assembly. By investing in tailored cleaning solutions, electronics manufacturers can uphold their commitment to quality while minimising the risk of defects in their products.

The Benefits of Tailored Industrial Cleaning Equipment

In conclusion, tailored industrial cleaning equipment plays a vital role in maintaining cleanliness across various sectors. From food and beverage to pharmaceuticals and aerospace, each industry has its own unique challenges that require specialised solutions. By investing in customised cleaning equipment, businesses can enhance operational efficiency, ensure compliance with health and safety regulations, and ultimately protect their reputation.

The benefits of tailored industrial cleaning solutions extend beyond mere compliance; they also contribute to improved productivity and reduced downtime. As industries continue to evolve and face new challenges, the importance of investing in tailored cleaning equipment will only grow. By prioritising cleanliness through specialised solutions, businesses can create safer working environments while delivering high-quality products that meet consumer expectations.